Product Center

JT-SL series raw material grinding aid

This series of cement raw material grinding aids are liquid products mainly composed of organic surfactants and complex alkanolamines, with other polyols as auxiliary components. They are generally brownish-opaque, odorless, and non-irritating, and do not harm human health.

raw material grinding aid

Details

I. Product Introduction

This series of cement raw material grinding aids are liquid products mainly composed of organic surfactants and complex alkanolamines, with other polyols as auxiliary components. They are generally brownish-black and opaque, odorless and non-irritating, and do not harm human health.

Specifications: 250 kg/barrel, 1 ton/barrel, and bulk packaging are available.

Density: (20℃±1℃): 1.15-1.26 (g/cm3)

PH value: (20℃±1℃): 6~9

Solid content: 36±1 (%)

Product shelf life: 12 months

Recommended dosage: 0.1%-0.2% (m/m) of the cement raw material weight

The use of this product in cement raw materials does not affect the composition of the cement raw materials.

II. Application Scope and Usage Effects

Suitable for tube mills and vertical mills for grinding cement raw materials, improving mill output, reducing grinding power consumption, improving cement raw material decomposition rate, improving clinker quality, and increasing kiln output.

When used in tube mills for producing cement raw materials, while maintaining consistent fineness, this grinding aid can increase mill output by more than 10%, reduce power consumption by 10-15%, improve cement raw material decomposition rate, improve clinker quality, reduce the total amount of SO2 emissions in kiln exhaust gas, and reduce coal consumption. It solves the problem of insufficient supply of cement raw materials and reduces equipment maintenance costs.

When used in vertical mills for producing cement raw materials, while maintaining consistent fineness, this grinding aid can increase mill output by 5-10%, reduce power consumption by 4-8%, stabilize the mill material layer thickness, reduce mill vibration speed, improve cement raw material decomposition rate, improve clinker quality, reduce the total amount of SO2 emissions in kiln exhaust gas, and reduce coal consumption. It solves the problem of insufficient supply of cement raw materials and reduces equipment maintenance costs.

III. Case Studies

Case 1: YF Cement Company

Comparison before and after using JT-SL10A grinding aid in a Φ4.2*8 single-bin air-swept mill for producing cement raw materials. See Table 1 for specific results.

Table 1: Statistics of changes (average value) before and after adding JT-SL10A grinding aid to cement raw materials

|

Time |

Grinding Aid Dosage (%) |

Raw Material Mill Output |

Raw Material Section Power Consumption (kWh) |

Raw Material Fineness (80μm sieve residue %) |

Particles <10μm (%) |

Particles >200μm (%) |

Raw Material Decomposition Rate (%) |

Clinker Coal Consumption (kg/t) |

|

Blank Period |

0 |

166 |

23.07 |

17.9 |

34.58 |

2.19 |

93.19 |

106.2 |

|

Experimental Period |

0.1 |

185 |

20.66 |

16.8 |

31.20 |

1.88 |

95.36 |

104.1 |

|

Difference |

|

+19 |

-2.41 |

-1.1 |

-3.38 |

-0.31 |

+2.17 |

-2.1 |

The comparison before and after the experiment shows that after adding the special grinding aid for raw materials, the mill output increased by an average of 19 tons/hour, an increase of 11.4%; power consumption decreased by an average of 2.41 kWh; the fineness of the raw material product decreased slightly; the content of particles below 10μm and above 200μm decreased; the particle size of the raw material product became more concentrated; the raw material decomposition rate increased, which is more conducive to clinker calcination; and the coal consumption per ton of clinker decreased by 2.1 kg.

Case 2: HH Cement Company

Comparison before and after using JT-SH20A grinding aid in an ATOX-50 vertical mill for producing cement raw materials. See Table 2 for specific results.

Table 2: Statistics of changes (average value) before and after adding JT-SL20A grinding aid to cement raw materials

|

Time |

Grinding Aid Dosage (%) |

Raw Material Mill Output (t/h) |

Raw Material Section Power Consumption (kWh) |

Raw Material Fineness (80μm sieve residue %) |

Mill Vibration |

Raw Material Decomposition Rate (%) |

Clinker Coal Consumption (kg/t) |

|

Blank Period |

0 |

386 |

16.65 |

19.2 |

2.66 |

93.32 |

109.3 |

|

Experimental Period |

0.2 |

416 |

15.62 |

18.8 |

2.45 |

94.46 |

106.1 |

|

Difference |

|

+30 |

-1.03 |

-0.4 |

-0.21 |

+1.14 |

-3.2 |

The comparison before and after the experiment shows that after adding the special grinding aid for raw materials, the mill output increased by an average of 30 tons/hour, an increase of 7.8%; power consumption decreased by an average of 1.03 kWh, a decrease of 6.2%; the fineness of the raw material product decreased slightly; mill vibration speed decreased; the stability of the vertical mill operation improved; the raw material decomposition rate increased, which is more conducive to clinker calcination; and the coal consumption per ton of clinker decreased by 3.2 kg.

IV. Value Created by Using Raw Material Grinding Aids

The economic value created by using special grinding aids in the production of cement raw materials is divided into two parts: direct economic value and indirect economic value.

(1) Direct Economic Value:

1. Increased mill output; tube mill output increased by more than 10%, and power consumption decreased by 10-15%; vertical mill output increased by 5-10%, and power consumption decreased by 4-8%.

2. Increased mill output, relatively lower mill operating rate, and reduced annual mill maintenance costs.

3.Improved decomposition rate of cement raw materials, and reduced coal consumption of cement clinker, reducing standard coal by 2-4kg/t;

4.Increased cement raw material output per unit time, increased cement clinker production; clinker is easier to burn, clinker output per unit time can be increased by 3-5%; total profit of clinker increases, compensating for insufficient clinker supply.

(II) Indirect economic value:

1.The particle distribution of cement raw materials is relatively concentrated, reducing the amount of clinker kiln scaling and processing time, and reducing the rate of kiln shutdown accidents;

2.Reduced fine particles of cement raw materials, reduced dust collection and fly ash, and improved stability of cement clinker quality.

3.Improve the decomposition rate of calcium carbonate, the CaO generated in advance enhances the adsorption and reaction of SO2, reducing the total emission of SO2 in the kiln tail gas;

V. Storage methods and conditions

This series of grinding aids is a weakly alkaline liquid. It is recommended to use plastic or stainless steel equipment for storage. Store in a sealed container. The storage equipment should be equipped with a circulation device, and the product should be circulated regularly to ensure product uniformity. The storage temperature is recommended from -10℃ to 40℃.

VI. Adding methods during use

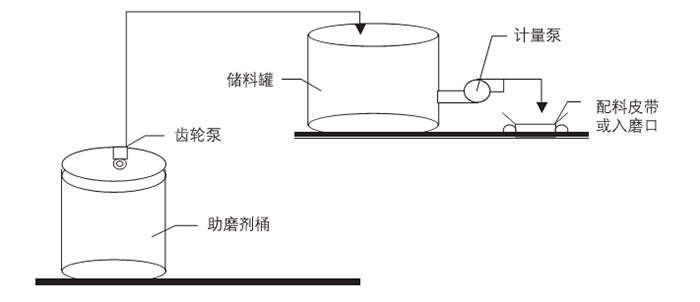

1. When it is not necessary to increase the adding height, a metering pump can be used directly for metering and adding;

2. When it is necessary to increase the adding height of the grinding aid, it is generally added by a two-stage pumping method,

The schematic diagram is as follows:

For companies using our company's grinding aids, we provide customers with storage tanks and related metering devices, as well as detection and control methods for the amount added.

VII. Precautions

(I) This grinding aid should be used after passing the inspection. Inspection methods include:

1. Homogeneity acceptance: Check the density, water content, pH value, and color of the newly arrived grinding aid to see if all indicators are within the allowable error range;

2. Small mill acceptance: Using the same batch of cement raw materials, according to the production ratio of cement raw materials, compare the qualified grinding aid with the newly arrived grinding aid, each grinding aid is milled 2 times simultaneously, discarding the first mill, using the second mill to test various indicators, the 80μm sieve residue of cement raw materials is within the range of ±0.5%, which is considered qualified;

When continuously using grinding aids, the first method is generally used. The second method is only used when there is a large difference in the quality of the grinding aids.

(II) When transporting and storing barrel grinding aids, prevent dropping, smashing, external force extrusion, and proximity to high temperatures. The stacking height should not exceed two barrels;

(III) Before use, check the company's identification before opening the seal, and confirm that the product and model are correct before use;

(IV) This product has mild corrosive properties to the skin. After skin contact, rinse with water. Do not ingest it;

(V) When using this product, if the ambient temperature is continuously lower than -5℃ for 5 days, insulation measures should be taken to prevent the product viscosity from increasing and affecting normal use.