Product Center

JT-W series high-efficiency enhanced cement grinding aid

This series is mainly applicable to silicate cement, ordinary silicate cement, compound silicate cement, slag silicate cement, fly ash silicate cement, and masonry cement. According to its function, it is divided into early-strength type, later-strength type, high-yield type, comprehensive type, and delayed-setting type products.

Cement grinding aid

Details

I. Product Characteristics

This series of products is liquid and is available in three packages: dispersed, ton, and 250kg barrels.

Color: Light yellow

Density: (20℃) 1.18-1.25 (g/cm3)

PH value: (20℃) 8.50-9.50

Solid content: 40-60 (%)

Suitable dosage: 0.025-0.1%

II. Scope of Application and Effects

This series is mainly suitable for silicate cement, ordinary silicate cement, composite silicate cement, slag silicate cement, fly ash silicate cement, and masonry cement.

According to its function, it is divided into early-strength type, late-strength type, high-yield type, comprehensive type, and retarding type products.

Early-strength type products, used in cement production, under the condition that the cement ratio and fineness control indicators are basically consistent, can increase the 3-day compressive strength of cement by more than 4.0 MPa, and the water demand for standard consistency of cement increases by less than 0.5%;

Late-strength type products, used in cement production, under the condition that the cement ratio and fineness control indicators are basically consistent, can increase the 28-day compressive strength of cement by more than 8.0 MPa, and the water demand for standard consistency of cement increases by less than 0.5%;

High-yield type products, used in the tube mill cement production process, under the condition that the cement ratio and fineness control indicators are basically consistent, can increase the output of the cement mill by more than 15%;

Comprehensive type products, used in the cement process, under the condition that the cement ratio and fineness control indicators are basically consistent, can reduce the clinker consumption by more than 6%, increase the admixture by the same proportion, and increase the output by more than 8%;

Retarding type products, used in the production of retarding cement, under the condition that the cement ratio and fineness control indicators are basically consistent, the initial and final setting time can be extended by more than 120 minutes, and the 3-day and 28-day compressive strength of cement increases by more than 0.5 MPa.

III. Case Studies

Table 1 Mill Status of P.C32.5 Cement Before and After Using Zhongsen Grinding Aid (Ø4.2m×13m Combined Grinding System of a Cement Plant in Guangxi)

|

Time |

Mixed Materials and Dosage /% |

Total Admixture /% |

Grinding Aid /% |

SO3 /% |

LOI /% |

Cl- /% |

80µm Residue /% |

Specific Surface Area M2/kg |

|||

|

Limestone |

Wet Fly Ash |

Fly Ash |

Shale |

||||||||

|

Before Using Grinding Aid |

16.5 |

7.9 |

5.4 |

Note 1 |

29.5 |

00 |

2.5 |

9.4 |

0.0 |

1.9 |

410.1 |

|

Normal Use Period |

25.8 |

3.4 |

10.8 |

Note 1 |

34.7 |

0.08 |

2.02 |

12.42 |

0.01 |

1.68 |

416.8 |

Note 1. In January 2009 and April 2010, shale was used to replace or partially replace fly ash.

Table 2 Performance Status of P.C32.5 Cement Before and After Using Zhongsen Grinding Aid

|

Time |

Standard Consistency % |

Setting Time /min |

Flexural Strength /MPa |

3-Day Compressive Strength / MPa |

28-Day Compressive Strength / MPa |

||||||

|

Initial Setting |

Final Setting |

3 Days |

28 Days |

Average |

Maximum |

Minimum |

Average |

Maximum |

Minimum |

||

|

Before Using Grinding Aid |

27.2 |

164 |

228 |

4.1 |

7.4 |

18.3 |

22.2 |

16.5 |

38.4 |

44.8 |

35.5 |

|

Normal Use Period |

26.9 |

182 |

246 |

4.2 |

7.3 |

18.9 |

21.4 |

16.6 |

39.1 |

42.0 |

37.7 |

Table 3 Mill Status of P•O42.5 Cement Before and After Using Zhongsen Grinding Aid (Ø4.2m×13m Combined Grinding System of a Cement Plant in Guangxi)

|

Time |

Mixed Materials and Dosage /% |

Total Admixture /% |

Grinding Aid /% |

SO3 /% |

LOI /% |

Cl- /% |

45µm Residue /% |

Specific Surface Area M2/kg |

|||

|

Limestone |

Slag |

Fly Ash |

Shale |

||||||||

|

Before Using Grinding Aid |

7.5 |

2 |

0 |

4 |

13.5 |

00 |

1.8 |

3.3 |

0.0 |

13.9 |

321 |

|

Normal Use Period |

8 |

4.5 |

1.5 |

6 |

20 |

0.06 |

1.8 |

4.3 |

0.006 |

12.8 |

330 |

Table 4 Performance Status of P•O42.5 Cement Before and After Using Zhongsen Grinding Aid

|

Time |

Standard Consistency /% |

Setting Time /min |

Flexural Strength /MPa |

3-Day Compressive Strength / MPa |

28-Day Compressive Strength /MPa |

||||||

|

Initial Setting |

Final Setting |

3 Days |

28 Days |

Average |

Maximum |

Minimum |

Average |

Maximum |

Minimum |

||

|

Before Using Grinding Aid |

26.6 |

158 |

208 |

5.2 |

8.3 |

25.9 |

28.9 |

24.5 |

55.2 |

56.9 |

53.2 |

|

Normal Use Period |

27.5 |

162 |

220 |

5.5 |

8.6 |

26.9 |

29.7 |

26.2 |

55.4 |

57.8 |

54.2 |

IV. Characteristics of Cement Using This Grinding Aid

1. The fluidity of the cement powder will increase;

2. The flow of the cement mortar will slightly increase;

3. The water demand for standard consistency will vary depending on the type and amount of mixed materials;

4. The fineness control of the finished cement is more sensitive to the 45μm sieve residue.

V. Method of Adding During Use

When no lifting height is required for adding, a metering pump can be used for metering and adding;

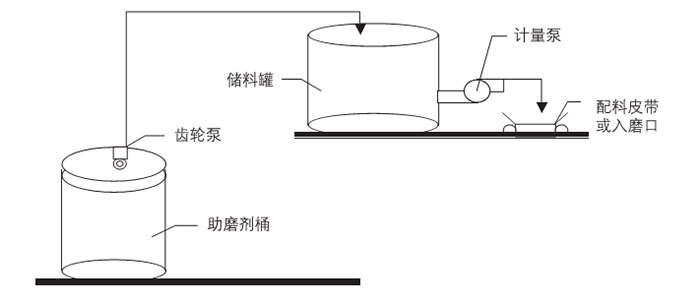

When the grinding aid needs to be lifted to a higher level for feeding, a two-stage pumping method is usually used for adding, as shown in the diagram below:

For companies using our grinding aid, we provide customers with storage tanks, relevant metering devices, and methods for testing and controlling the feeding amount.

VI. Precautions

1. This grinding aid should be used after passing the inspection. Inspection methods include:

1) A relatively simple method is to check the density, pH value, color, or solid content of the newly arrived grinding aid and a sample of the grinding aid that has been proven qualified after use under the same temperature conditions. When the two are within the error range, it can be considered qualified for use;

2) Use a cement without additives with a composition identical to the cement produced. In the same laboratory, conduct cement strength mixing tests using samples of the grinding aid that have been proven qualified after use and samples of the newly arrived grinding aid. When the three-day strength of the two is within the error range, it is considered qualified; the first method is generally used for continuous use of the grinding aid, and the second method is only used when there is a significant difference in the quality of the grinding aid.

2. During handling and storage, this grinding aid should be protected from dropping, impact, external pressure, and high temperatures. The stacking height should not exceed two barrels;

3. Before use, check the company's identification before opening the seal, and confirm that the product and model are correct before use;

4. This product has mild corrosive properties to the skin. After skin contact, rinse with water. Do not ingest;

5. When using this product, if the ambient temperature is continuously below -5℃ for 5 days, insulation measures should be taken to prevent product crystallization from affecting normal use.

6. The shelf life of this product is 12 months.