Product Center

JT-ZX series concrete water reducer,Water-reducing admixture for concrete

This series of defoaming agents are liquid products mainly composed of organic alkanolamine substances, with auxiliary functional additives. They are generally brownish-transparent, odorless, and non-irritating, and do not harm human health or concrete workability.

Concrete reducing agent

Details

In the construction industry, the search for high - quality building materials is an ongoing pursuit. One such crucial component is the Water-reducing admixture for concrete, and Chinese manufacturers are making significant strides in this area.

China has long been known for its manufacturing prowess, and when it comes to Water-reducing admixture for concrete, Chinese factories are at the forefront. These manufacturers offer some of the best water - reducing admixtures in the market.

The newest water - reducing admixtures for concrete from Chinese suppliers are of top - notch quality. They are designed with advanced formulas that not only effectively reduce the amount of water needed in concrete mixtures but also enhance the overall performance of the concrete. These admixtures are durable, ensuring that the concrete retains its strength and integrity over time.

For those looking for cost - effective solutions, Chinese manufacturers also provide cheap yet high - quality water - reducing admixtures. They often offer discounts, especially for wholesale orders. Companies can get a detailed quotation and pricelist from these suppliers. And if you're not sure about the product, many of them are willing to provide free samples.

What's more, these products come with CE certification, which is a testament to their compliance with international standards. The Chinese manufacturers are also open to customization. Whether you need a customized water - reducing admixture for a special project or an OEM service, they can meet your requirements.

There are many famous brands of Water-reducing admixture for concrete from China. These brands are known for their classy and fancy features that set them apart from the competition. Many exporters from China are ready to supply these products to the global market.

If you are in the market for a Water-reducing admixture for concrete, look no further than the manufacturers in China. They have the in - stock products, and with their reliable supply sources, you can be sure to get a quality product at a reasonable price. Whether you are a construction company or a builder, these Chinese - made water - reducing admixtures are an excellent choice for your concrete projects.

I. Product Introduction

This series of water reducers are liquid products mainly composed of organic alkanolamine substances, with auxiliary functional admixtures. They are generally brownish-transparent, odorless, and do not harm human health or concrete workability.

1. Specifications: 250 kg/barrel, 1 ton/barrel, and bulk packaging.

2. Density (20℃): 1.01±0.03g/cm³

3. PH value (20℃): 9.0±1.0

4. Chloride ion content: ≤0.1%

5. Alkali content: ≤1.0%

6. Suitable Dosage: 0.5-0.6% of the total mass of cementitious materials. The optimal dosage should be determined through trial mixing.

II. Scope of Application and Usage Effects:

1. Scope of Application: Mainly applicable to concrete mixing plants, pipe pile enterprises, component enterprises, railway and water conservancy projects, etc.

2. Usage Effects:

(1) When adding 0.5-0.6% of this enhancer (based on the total mass of cementitious materials) without changing the concrete mix ratio, the 7-day compressive strength of the concrete can be increased by 3-5 MPa and the 28-day compressive strength by 3-8 MPa. At the same time, the workability of the concrete is significantly improved;

(2) While maintaining the same concrete strength, workability, and water-cement ratio, the cement content can be reduced by 10-20%. This ensures the comprehensive performance and strength of the concrete while significantly increasing the slurry volume and improving the rheological properties of the concrete.

III. Usage Method

1. Dosage: 0.5-0.6% of the total mass of cementitious materials. The optimal dosage should be determined through trial mixing;

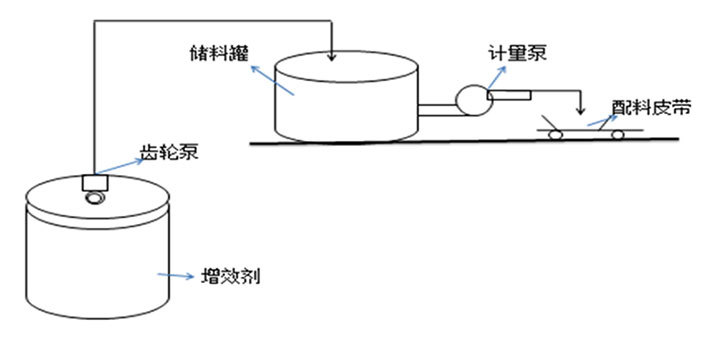

2. Specific Method: When no height increase is needed for addition, a metering pump can be directly used for metering and addition;

When it is necessary to increase the feeding height of the enhancer, a two-stage pumping method is generally used for addition. The schematic diagram is as follows:

For companies using our water reducer, we provide customers with storage tanks, related metering devices, and methods for detecting and controlling the feeding amount.

III. Usage Examples

1. Trial mixing test results from S mixing plant in Nanning City, Guangxi

|

Test No. |

Concrete Design Grade |

Cement kg/m³ |

Mineral Powder kg/m³ |

Fly Ash kg/m³ |

River Sand kg/m³ |

Stone kg/m³ |

Water kg/m³ |

Admixture kg/m³ |

Enhancer kg/m³ |

Slump at Discharge/mm |

Spread at Discharge/mm |

Slump after 1 Hour/mm |

Spread after 1 Hour/mm |

7-Day Compressive Strength/MPa |

28-Day Compressive Strength/MPa |

|

ZS-1 |

C30 |

180 |

80 |

85 |

880 |

1010 |

162 |

9.66 |

0 |

205 |

490 |

190 |

410 |

29.0 |

42.6 |

|

ZS-2 |

C30 |

180 |

80 |

85 |

880 |

1010 |

162 |

9.66 |

2.0 |

225 |

606 |

190 |

535 |

33.4 |

48.5 |

Note: All raw materials were provided by the mixing plant. The enhancer dosage was 0.6% of the total mass of cementitious materials, and the concrete mix ratio was not adjusted.

2. Industrial trial mixing test results from X mixing plant in Nanning City, Guangxi Province

|

Test No. |

Concrete Design Grade |

Cement kg/m³ |

Fly Ash kg/m³ |

River Sand kg/m³ |

Manufactured Sand kg/m³ |

Stone kg/m³ |

Water kg/m³ |

Admixture kg/m³ |

Enhancer kg/m³ |

Slump at Discharge/mm |

Spread at Discharge/mm |

Slump after 1 Hour/mm |

Spread after 1 Hour/mm |

7-Day Compressive Strength/MPa |

28-Day Compressive Strength/MPa |

|

ZS-1 |

C30 |

275 |

60 |

450 |

479 |

960 |

158 |

8.0 |

0 |

195 |

550 |

195 |

415 |

30.4 |

37.8 |

|

ZS-2 |

C30 |

250 |

60 |

460 |

489 |

960 |

146 |

8.0 |

1.86 |

205 |

585 |

195 |

535 |

32.4 |

40.8 |

Note: All raw materials were provided by the mixing plant. The enhancer dosage was 0.6% of the total mass of cementitious materials, the cement content was reduced by 25kg, and the water-cement ratio remained unchanged.

V. Economic Benefit Calculation

Using this enhancer, while ensuring the workability and compressive strength of the concrete remain unchanged, the cement consumption can be reduced by 10-20%, with the same amount of manufactured sand or river sand, fly ash, etc., used as a supplement.

Direct Economic Benefit = Cement Price × Cement Savings - Enhancer Price × Enhancer Usage - Manufactured Sand Price × Manufactured Sand Increase + Admixture Price × Admixture Savings

VI. Usage Characteristics:

1. Improves the workability of fresh concrete, improves workability, and reduces bleeding;

2. Increases the density of concrete, improves impermeability, and reduces cracks in concrete;

3. Improves the freeze-thaw resistance and carbonation resistance of concrete;

4. This product is non-toxic and harmless, with zero emissions during production, and is a green and environmentally friendly building material.

VII. Precautions

1. Before use, first check the company's logo according to the factory inspection report and label to confirm that the product and model are correct before use;

2. When further verifying product performance, the following methods can be used:

3. Consistency acceptance: Under the same temperature conditions, the density, PH, and solid content of the newly arrived enhancer and the qualified retained sample of the used enhancer are tested. When the difference in density is ±0.02, the difference in PH value is ±0.6, and the difference in solid content is ±2%, it is considered qualified;

4. A mortar compressive strength comparison test should be conducted based on the proportion of cement, fly ash, and mineral powder in the total amount of cementitious materials in a certain type of labeled concrete mix. During the test, both newly introduced and previously qualified efficiency enhancers are added separately. When the 7-day compressive strength of the mortar containing both types of efficiency enhancers is within the allowable ±5% error range, the newly introduced efficiency enhancer is considered qualified.

5. It is recommended to use the first method when using the efficiency enhancer continuously. When there is a significant difference in the quality of the efficiency enhancer, the second method should be used.

6. During handling and storage, this efficiency enhancer should be protected from dropping, impact, external force compression, and high temperatures. The stacking height should not exceed two barrels.

7. This product has mild corrosive properties to the skin. In case of skin contact, rinse with clean water immediately. Do not ingest.

8. This product can be added simultaneously with a water reducer.

9. Shelf life: 6 months.