Product Center

JT-HPSA water-reducing polycarboxylate superplasticizer,Concrete plasticizer additive

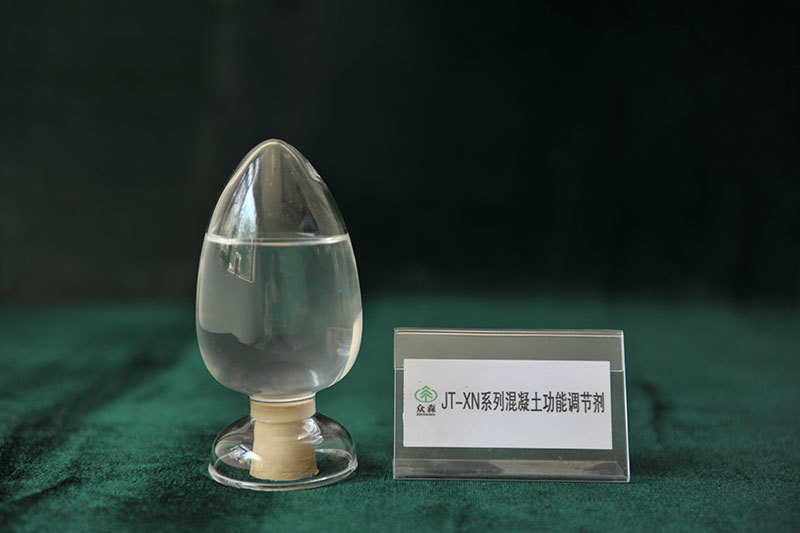

Zhongsen brand HPSA water-reducing polycarboxylate superplasticizer is the latest leading product at home and abroad. It features high water reduction rate, low dosage, good compatibility with cement, small slump loss, and no pollution. It also improves various performance indicators of fresh concrete and enhances workability. This product is a colorless transparent liquid, non-toxic, non-corrosive, non-flammable, non-corrosive to steel bars, and harmless to human health.

Concrete water reducer

Details

In the construction industry, a game - changing product has been making waves - the Concrete Plasticizer Additive.Concrete is the backbone of most construction projects, but traditional concrete mixtures often have limitations. The Concrete Plasticizer Additive is here to overcome these challenges. This innovative additive is designed to enhance the workability of concrete without sacrificing its strength.

When added to the concrete mix, the plasticizer additive works by reducing the amount of water needed while maintaining the desired consistency. This is a significant advantage as it helps in preventing issues such as shrinkage cracks that are common when too much water is used in the mix.

One of the key features of the Concrete Plasticizer Additive is its ability to increase the fluidity of the concrete. This allows for easier pouring and better compaction, especially in complex or hard - to - reach areas of a construction site. It enables concrete to flow more smoothly around reinforcing bars and into formwork, ensuring a more uniform and structurally sound end product.

Moreover, this additive is also environmentally friendly. By reducing the water - cement ratio, it can contribute to a reduction in the carbon footprint associated with concrete production. This is in line with the growing trend in the construction industry towards more sustainable building practices.

Manufacturers of the Concrete Plasticizer Additive are constantly researching and developing to improve its performance. New formulations are being tested to offer even greater benefits such as enhanced durability and resistance to chemical attacks.

In the market, construction companies are quickly recognizing the value of this additive. It not only improves the quality of the concrete but also can lead to cost savings. With easier handling and less waste due to improved workability, projects can be completed more efficiently.

The Concrete Plasticizer Additive is indeed a remarkable product that is reshaping the way we think about concrete in construction. As the construction industry continues to evolve, this additive is set to play an increasingly important role in building stronger, more durable, and more sustainable structures.

Zongshen brand HPSA water-reducing polycarboxylate superplasticizer is currently the leading product at home and abroad, with the characteristics of high water reduction rate, low dosage, good adaptability to cement, small slump loss, and no pollution. At the same time, it has multiple functions such as improving various performance indicators of fresh concrete and improving workability. This product is a colorless and transparent liquid, non-toxic, non-corrosive, non-flammable, has no corrosive effect on steel bars, and is harmless to human health.

This product refers to and implements GB/T8076-2008 "Concrete Admixtures", GB/T8077-2012 "Concrete Admixture Homogeneity Test Method", and JG/T223-2007 "Polycarboxylate High-Performance Water Reducer" standards.

I. Technical Indicators

1. Pumping performance: It has significant pumpability. Compared with the benchmark concrete, under the same water-cement ratio, the slump ≥220mm, and the net slump change in 1h ≤50mm.

2. Enhancement effect: Under the premise of the same slump and equal cement consumption as the benchmark concrete, the water reduction rate ≥25%, the strength of concrete at all ages is significantly improved, the 7d compressive strength ratio ≥150%, and the 28d compressive strength ratio ≥140%.

3. Workability: It improves the workability, water retention, and bleeding of fresh concrete.

4. Smooth surface: Concrete using this product has strong cohesiveness, low air content, and low bleeding rate, which can effectively improve the surface smoothness and beauty of various clear water concrete such as elevated roads, expressways, and bridges.

5. Special effects: When preparing high-strength concrete, its elastic modulus, impermeability, shrinkage resistance, creep resistance, and durability can all meet the requirements.

6. Physicochemical indicators: Colorless or light brown transparent liquid, solid content 40±1%, water reduction rate ≥25%, density 1.08±0.02kg/m³.

II. Homogeneity Indicators

According to the product performance indicators and user requirements, it complies with national, industry, and enterprise standards.

III. Application Scope

This product is suitable for various pumped concrete, mass concrete, high-rise buildings, elevated roads, expressways, bridges, hydraulic concrete, and underground and underwater poured concrete. It is especially suitable for key projects and concrete with special requirements.

IV. Application Examples

C30 concrete test results from a Zhonghlian pre-mixed concrete plant

|

Test Number |

Cement kg/m³ |

Mineral Powder kg/m³ |

Fly Ash kg/m³ |

Machine-made Sand kg/m³ |

1-2 Stone kg/m³ |

1-3 Stone kg/m³ |

Water kg/m³ |

Admixture/% |

Initial Performance/mm |

2h Performance/mm |

|

Admixture Used |

230 |

90 |

80 |

860 |

850 |

135 |

165 |

2.2 |

220/540 |

160/400 |

|

Zongshen admixture |

230 |

90 |

80 |

860 |

850 |

135 |

165 |

2.2 |

230/550 |

220/530 |

Remarks: 1. The solid content of the two water reducers is consistent; 2. The proportion of Zongshen water-reducing water reducer in the water reducer is 70%.

V. Usage

1. The dosage range of this product is 0.5-0.8% (based on the amount of cementitious materials). According to the adaptability to cement, temperature changes, and concrete slump requirements, the optimal dosage can be determined within the recommended range.

2. When calculating the water consumption of concrete, the water content in the liquid agent should be deducted.

3. When using this product, the adaptability to cement should be tested in advance according to the concrete mix design.

4. This product is a high-content water reducer. Before compounding with other types of admixtures, it must be determined through testing.

VI. Packaging and Storage

1. Tank trucks can be used for transportation; 1000kg/barrel plastic barrels; special packaging can also be made according to user requirements.

2. The product warranty period is one year. If there is any precipitation within the warranty period, it can be used after stirring without affecting the effect.

VII. Precautions

1. When the cement type is updated or new cement is introduced, a compatibility test with the cement should be carried out.

2. For concrete requiring retarding, the setting time should be tested in advance according to the concrete mix design.

3. The correct dosage must be added according to the test mix ratio, and during concrete pouring, the construction specifications must be strictly followed.

4. When compounding with other admixtures, their compatibility should be tested first.

5. During winter construction, to improve the early strength of concrete, the cement content of concrete should be adjusted appropriately.

6. As with conventional concrete engineering, curing must be strengthened according to construction specifications.