Product Center

Cement mineralizer

This series of grinding aids are liquid products mainly composed of organic surfactants, polyols, sugars, and alkanolamines, with a small amount of inorganic salts as auxiliary components. They are generally dark brownish, non-transparent, odorless, and non-irritating, and do not harm human health or the workability of cement concrete.

Cement mineralizer

Details

This series of mineralizers are liquid products mainly composed of organic carboxylates, alkanolamines, and polyols, with other inorganic salts as auxiliary components. They are generally brownish-transparent, odorless, non-irritating, and do not harm human health or the workability of cement concrete.

Specifications: 250 kg/barrel, 1 ton/barrel, and bulk.

Density: (20℃±1℃) 1.10-1.30 (g/cm³)

PH value: (20℃±1℃) 8~11

Solid content: 35~65 (%)

Product shelf life: 12 months. The use of this product in cement does not affect the shelf life of the cement.

Recommended dosage: 0.03-0.2% (m/m) of the cement weight.

II. Scope of application and effects

This series of mineralizer products are mainly suitable for silicate cement, ordinary silicate cement, composite silicate cement, slag silicate cement, fly ash silicate cement, masonry cement, and volcanic ash silicate cement. They enhance the mineral components in cement, increase the amount of cement hydration products, and improve cement quality, thus reducing the consumption of cement clinker and improving the overall efficiency of cement production.

Using this product in addition to existing grinding aids, while maintaining the cement fineness control indicators, can further reduce the clinker consumption by more than 4% and increase the cement mill output by more than 8%, while maintaining or slightly improving the cement workability.

III. Application examples

|

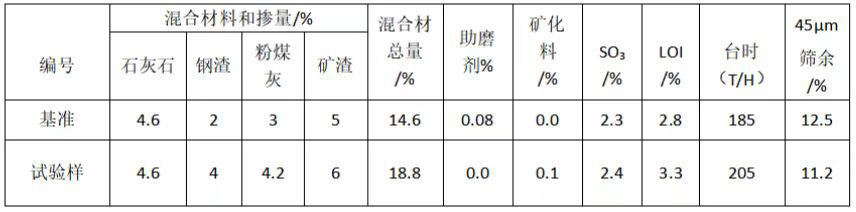

Table 1: Mill conditions of P·O42.5 cement before and after using Zhongsen mineralizer (Ø4.2m×13m combined grinding system of a certain cement plant in Shandong)

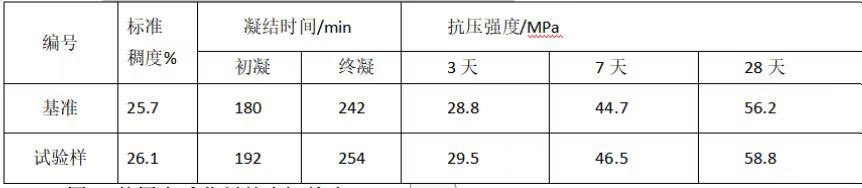

Table 2: Performance of P·C42.5 cement before and after using Zhongsen mineralizer

|

IV. Characteristics of cement using this mineralizer

1. Increased fluidity of cement powder;

2. Slightly increased fluidity of cement mortar;

3. Slightly changed water demand for standard consistency (when the type and amount of admixture are the same);

4. Slightly prolonged setting time;

5. The 45μm residue of cement will decrease, but the specific surface area will not increase. The 45μm residue is used to control the fineness of the finished product.

V. Storage methods and conditions

This series of mineralizers are weakly alkaline liquids. It is recommended to use sealed plastic containers for storage. The storage equipment should be equipped with a circulation device, and the product should be circulated regularly to ensure uniformity. The recommended storage temperature is -10℃-40℃.

VI. Adding method during use

When no heightening of the addition is needed, a metering pump can be used for metering and adding;

When it is necessary to increase the feeding height of the mineralizer, a two-stage pumping method is generally used.

VII. Precautions

1. This mineralizer should be used after passing inspection. Inspection methods include:

(1) A simple method is to test the density, PH value, color, or solid content of the newly arrived mineralizer and the sample of the mineralizer that has been proven qualified under the same temperature conditions. If the two are within the error range, it can be considered qualified for use;

(2) Use a cement without additives with the same composition as the cement being produced. In the same laboratory, conduct cement strength mixing tests using both the qualified sample JT-KH and a sample of the newly arrived mineralizer. If the three-day strength of the two is within the error range, it is considered qualified;

When using the mineralizer continuously, generally one method is used. Only when there is a large difference in the quality of the mineralizer are both methods used.

2. When handling and storing barreled mineralizers, prevent dropping, smashing, external force compression, and proximity to high temperatures. The stacking height should not exceed two barrels;

3. Check the company's label before opening the seal and confirm that the product and model are correct before use;

4. This product has mild corrosive properties to the skin. After skin contact, rinse with water. Do not ingest;

5. When using this product, if the ambient temperature is continuously below -5℃ for 5 days, insulation measures should be taken to prevent the product viscosity from increasing and affecting normal use;

6. Shelf life of this product: 12 months.