JT-IICS Cement Grinding Aid

1. Product introduction

The main components of this series of grinding aids are mainly organic surfactants, alcohol amines, and other liquid products supplemented by alcohols. They are generally brown and transparent, have no irritating odor, and do not harm human health and the performance of cement concrete.

Specifications: 250 kg/barrel, 1 ton/barrel, bulk three specifications

Density: (20℃±1℃)1.15-1.25(g/cm³)

PH value: (20℃±1℃) 8~10

Solid content: 50~70(%)

Product shelf life: 12 months, the use of the product in cement does not affect the cement shelf life

Recommended dosage: 0.02-0.05% of cement mass (m/m)

2. Scope and performance

This series of products are mainly suitable for Portland cement, ordinary Portland cement, composite Portland cement, slag Portland cement, fly ash Portland cement, masonry cement and pozzolanic Portland cement.

According to their functions, they are divided into early-strength type, post-strength type, production-increasing type, and comprehensive type.

Early-strength products, used in the cement production process, can improve the 3-day compressive strength of cement by more than 4.0MPa under the condition that the cement ratio and fineness control indicators are basically the same, and the increase in water demand for standard consistency of cement is less than 0.5%. ;

The post-strength product is used in the cement production process. Under the condition that the cement ratio and fineness control indicators are basically the same, the 28-day compressive strength of the cement can be increased by more than 8.0MPa, and the increase in water demand for the standard consistency of the cement is less than 0.5%. ;

The production-increasing product is used in the process of cement production by tube mill. Under the condition that the cement ratio and fineness control indicators are basically the same, the hourly output of the cement mill can be increased by more than 15%;

Comprehensive product, used in the cement process, under the condition that the cement ratio and fineness control indicators are basically the same, it can reduce the amount of cement clinker by more than 6%, increase the amount of mixed materials in the same proportion, and can increase production by more than 8%. ;

3. Use examples

Table 1 Conditions of the P•C 42.5 cement before and after using Zhongsen grinding aid (Ø4.2m×11m combined grinding system in a cement plant in Zhejiang)

|

ID |

Mixed materials and dosage/% |

Total amount of mixed materials/% |

Grinding aid |

SO₃ |

LOI |

Taiwan hour (T/H) |

45μm |

Comparison table |

|||

|

Limestone |

Slag |

fly ash |

Mineral powder |

||||||||

|

blank |

4.6 |

2 |

4.1 |

6.5 |

17.2 |

0.0 |

2.1 |

3.3 |

125 |

11.8 |

342 |

|

Test sample |

6.4 |

4 |

4.2 |

9.1 |

23.5 |

0.03 |

2.2 |

4.3 |

180 |

11.2 |

344 |

Table 2 Performance of P·C 42.5 cement before and after using Zhongsen grinding aid

| ID |

Standard |

Coagulation time/min |

Compressive strength/MPa |

|||

|

Initial coagulation |

Final coagulation |

3 days |

7 days |

28 days |

||

|

blank |

26.8 |

208 |

262 |

25.8 |

40.7 |

53.2 |

|

Test sample |

27.1 |

212 |

268 |

26.0 |

47.5 |

60.8 |

4. Characteristics of cement using this grinding aid

1. The fluidity of cement powder will increase;

2. The fluidity of cement mortar increases slightly;

3. The water consumption of the standard consistency is slightly changed (when the amount of the mixture is the same);

4. The setting time is slightly shortened;

5. The 45μm sieve residue of cement will decrease, but the specific surface area value does not increase, and the 45μm sieve residue is used to control the grinding fineness.

5. Storage methods and conditions

This series of grinding aids are weak alkaline liquids. It is recommended to use plastic product storage equipment for airtight storage. The storage equipment should be equipped with a circulation device, and the products should be recycled regularly to ensure product uniformity. The recommended storage temperature is -10℃-40℃.

6. How to join when using

You can directly use the metering pump to meter in without raising the addition height;

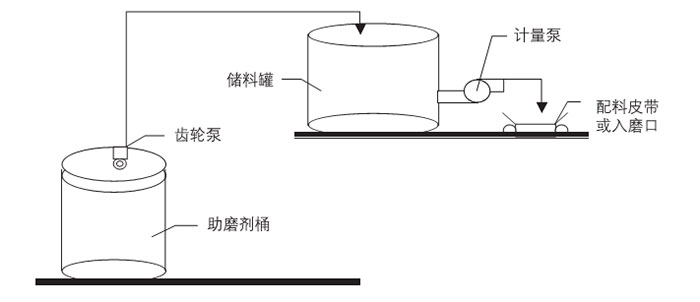

When it is necessary to increase the feeding height of grinding aid, it is generally added by means of secondary pumping, as shown in the diagram below:

For companies that use our grinding aids, we provide customers with storage tanks and related metering devices and methods of testing and controlling the amount of feed.

7. Precautions

1. This grinding aid should be used after passing the inspection. Acceptance inspection methods are:

(1) A relatively simple method is to detect the density, PH value and color, or solid content of the newly arrived grinding aid and the retained sample of the certified grinding aid under the same temperature conditions, when the two are in error. It can be considered qualified and put into use when it is within the scope;

(2) Use a kind of additive-free cement with the same composition as the production cement, and at the same time in the same laboratory, use the retained sample JT-IICS of the grinding aid that has been certified as qualified and the newly arrived grinding aid to sample the cement. In the strength blending test, when the three-day strength of the two is within the error range, it is qualified; the first method is generally used when the grinding aid is used continuously, and the second method is only used when there is a big difference in the quality of the grinding aid. .

2. The barreled grinding aid should be prevented from being dropped, smashed, squeezed by external force and approaching high temperature during handling and storage, and the stacking height should not exceed two barrels;

3. Before use, check the company's logo and then open the cover to confirm that the product and model are correct before putting it into use;

4. This product is slightly corrosive to the skin. After contact with the skin, it should be washed with water, and it should not be eaten by mouth;

5. When using this product, when the ambient temperature is lower than -5°C for 5 consecutive days, insulation measures should be taken to prevent the increase of product viscosity from affecting normal use;

6. The shelf life of this product is: 12 months.

ONLINE MESSAGE

Related Products

CONTACT US

Tel :+86-0531-89731661

Tel:+86-0531-82988289

Add:13th Floor, Block C, Eurasia Grand View, No. 67, Sunshine New Road, Shizhong District, Jinan City, Shandong Province

Copyright © 2022 Shandong Zhongsen Technology Co., Ltd. All Rights Reserved. 鲁ICP备13023259号-1 Powerby : 300.cn jinan SEO